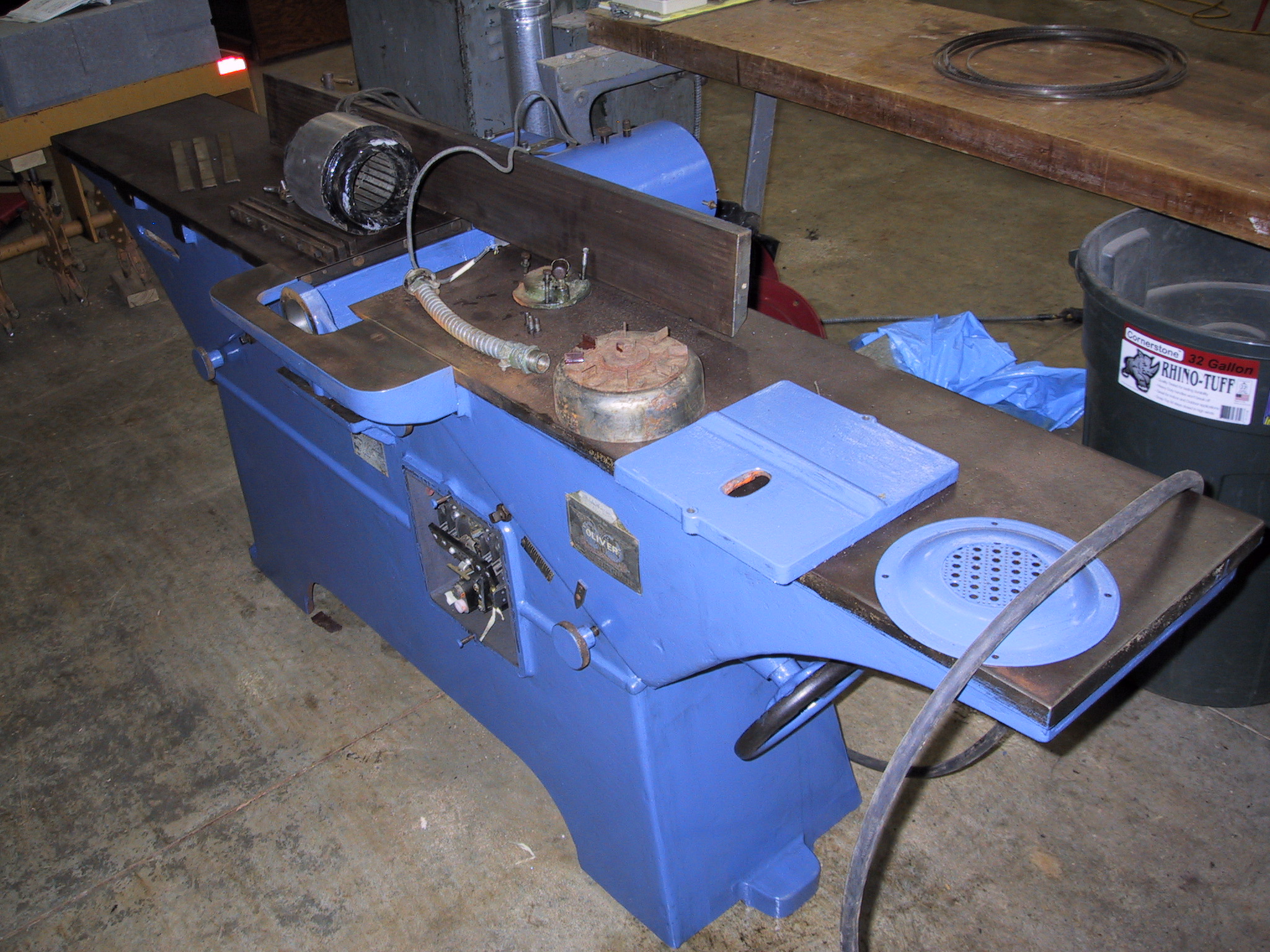

12"

Oliver jointer rescued from a farmer's field, sitting outside.

$50 gamble. It was all there though, took the fence

off to

move. His tractor was able to lift it.

Teardown.

This is a direct drive 3 phase motor driven model

with the 3

cutting blades held in a straight slot rather than one with a

dovetail which seems a bit more secure.

stator

housing integral with cutter head carrier, painted. If that

chip

exit slot wasn't there this would have filled with water and the motor

would have been ruined

thick

stator insulation that was over the motor windings was damaged a bit,

the cracked stuff was cut away and repaired with some sealant

motor

rotor/cutter head assembly new shielded bearings installed,

chipmunks put nut shells in the old ones after removing the old rubber

seals

main

castings closer to assembly. the table ends just run up the

ways

on the base casting when you crank the handwheels underneath.

Heavy table surfaces are around 3/4" thick, tables had to be

installed with forklift

getting

closer. There is no outer motor bearing on the fan end of the

motor, the rotor is just cantilevered inside the stator and is

supported only by the cutter head bearings

ready

to work. You can hear it run, but there is no vibration-

1700lbs.

New blades. The cast iron top was resurfaced first

with a

single edge razor blade in a heavy duty 12" long holder with a

screwdriver type handle, then with very fine paper on a DA sander to

polish..

Cast iron does pretty well outside as long as nothing is

sitting

on it to trap water. This was outside for a long time.

Oliver

is still in business, they make a very similar machine now, but it has

dovetail ways and a conventional motor with belt drive for $5400.

There it goes, sold. I had to add blocks so I could

lift

the pallet I built from the ends, following the liftgate up with the

forklift.

Wouldn't fit in the truck sideways- too long, had to be moved

with 2 pallet jacks.